Specs/CAD

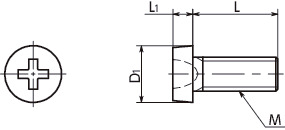

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | D1 | L1 | Bit Part No. | Tensile Breaking Load (N)*1 |

Torsional Torque (N・m)*1 |

Qty per Pack | Mass (g) |

Price (USD) |

CAD Download |

QTY (Pack) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SPE-M1.2-1.5-MC1 | M1.2 | 0.25 | 1.5 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 10 | 0.038 | 17.15 | CAD | Cart |

| SPE-M1.2-1.8-MC1 | M1.2 | 0.25 | 1.8 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 10 | 0.038 | 17.15 | CAD | Cart |

| SPE-M1.2-2-MC1 | M1.2 | 0.25 | 2 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 10 | 0.039 | 17.15 | CAD | Cart |

| SPE-M1.2-2.5-MC1 | M1.2 | 0.25 | 2.5 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 10 | 0.039 | 17.15 | CAD | Cart |

| SPE-M1.2-3-MC1 | M1.2 | 0.25 | 3 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 10 | 0.039 | 17.15 | CAD | Cart |

| SPE-M1.2-3.5-MC1 | M1.2 | 0.25 | 3.5 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 10 | 0.04 | 17.15 | CAD | Cart |

| SPE-M1.2-4-MC1 | M1.2 | 0.25 | 4 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 10 | 0.04 | 17.15 | CAD | Cart |

| SPE-M1.2-1.5-MC1(100) | M1.2 | 0.25 | 1.5 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 100 | 0.038 | 61.60 | CAD | Cart |

| SPE-M1.2-1.8-MC1(100) | M1.2 | 0.25 | 1.8 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 100 | 0.038 | 61.60 | CAD | Cart |

| SPE-M1.2-2-MC1(100) | M1.2 | 0.25 | 2 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 100 | 0.039 | 61.60 | CAD | Cart |

| SPE-M1.2-2.5-MC1(100) | M1.2 | 0.25 | 2.5 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 100 | 0.039 | 61.60 | CAD | Cart |

| SPE-M1.2-3-MC1(100) | M1.2 | 0.25 | 3 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 100 | 0.039 | 61.60 | CAD | Cart |

| SPE-M1.2-3.5-MC1(100) | M1.2 | 0.25 | 3.5 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 100 | 0.04 | 61.60 | CAD | Cart |

| SPE-M1.2-4-MC1(100) | M1.2 | 0.25 | 4 | 1.8 | 0.5 | SKCHB-M1.2 | 58 | 0.027 | 100 | 0.04 | 61.60 | CAD | Cart |

| SPE-M1.4-2-MC1 | M1.4 | 0.3 | 2 | 2 | 0.5 | SKCHB-M1.4 | 82 | 0.030 | 10 | 0.048 | 17.15 | CAD | Cart |

| SPE-M1.4-2.5-MC1 | M1.4 | 0.3 | 2.5 | 2 | 0.5 | SKCHB-M1.4 | 82 | 0.030 | 10 | 0.049 | 17.15 | CAD | Cart |

| SPE-M1.4-3-MC1 | M1.4 | 0.3 | 3 | 2 | 0.5 | SKCHB-M1.4 | 82 | 0.030 | 10 | 0.049 | 17.15 | CAD | Cart |

| SPE-M1.4-3.5-MC1 | M1.4 | 0.3 | 3.5 | 2 | 0.5 | SKCHB-M1.4 | 82 | 0.030 | 10 | 0.049 | 17.15 | CAD | Cart |

| SPE-M1.4-4-MC1 | M1.4 | 0.3 | 4 | 2 | 0.5 | SKCHB-M1.4 | 82 | 0.030 | 10 | 0.05 | 17.15 | CAD | Cart |

| SPE-M1.4-6-MC1 | M1.4 | 0.3 | 6 | 2 | 0.5 | SKCHB-M1.4 | 82 | 0.030 | 10 | 0.05 | 17.15 | CAD | Cart |

| SPE-M1.4-2-MC1(100) | M1.4 | 0.3 | 2 | 2 | 0.5 | SKCHB-M1.4 | 82 | 0.030 | 100 | 0.048 | 61.60 | CAD | Cart |

| SPE-M1.4-2.5-MC1(100) | M1.4 | 0.3 | 2.5 | 2 | 0.5 | SKCHB-M1.4 | 82 | 0.030 | 100 | 0.049 | 61.60 | CAD | Cart |

| SPE-M1.4-3-MC1(100) | M1.4 | 0.3 | 3 | 2 | 0.5 | SKCHB-M1.4 | 82 | 0.030 | 100 | 0.049 | 61.60 | CAD | Cart |

| SPE-M1.4-3.5-MC1(100) | M1.4 | 0.3 | 3.5 | 2 | 0.5 | SKCHB-M1.4 | 82 | 0.030 | 100 | 0.049 | 61.60 | CAD | Cart |

| SPE-M1.4-4-MC1(100) | M1.4 | 0.3 | 4 | 2 | 0.5 | SKCHB-M1.4 | 82 | 0.030 | 100 | 0.05 | 61.60 | CAD | Cart |

| SPE-M1.4-6-MC1(100) | M1.4 | 0.3 | 6 | 2 | 0.5 | SKCHB-M1.4 | 82 | 0.030 | 100 | 0.05 | 61.60 | CAD | Cart |

| SPE-M1.6-2-MC1 | M1.6 | 0.35 | 2 | 2.3 | 0.5 | SKCHB-M1.6 | 94 | 0.040 | 10 | 0.078 | 17.15 | CAD | Cart |

| SPE-M1.6-2.5-MC1 | M1.6 | 0.35 | 2.5 | 2.3 | 0.5 | SKCHB-M1.6 | 94 | 0.040 | 10 | 0.079 | 17.15 | CAD | Cart |

| SPE-M1.6-3-MC1 | M1.6 | 0.35 | 3 | 2.3 | 0.5 | SKCHB-M1.6 | 94 | 0.040 | 10 | 0.079 | 17.15 | CAD | Cart |

| SPE-M1.6-3.5-MC1 | M1.6 | 0.35 | 3.5 | 2.3 | 0.5 | SKCHB-M1.6 | 94 | 0.040 | 10 | 0.079 | 17.15 | CAD | Cart |

| SPE-M1.6-4-MC1 | M1.6 | 0.35 | 4 | 2.3 | 0.5 | SKCHB-M1.6 | 94 | 0.040 | 10 | 0.08 | 17.15 | CAD | Cart |

| SPE-M1.6-6-MC1 | M1.6 | 0.35 | 6 | 2.3 | 0.5 | SKCHB-M1.6 | 94 | 0.040 | 10 | 0.08 | 17.15 | CAD | Cart |

| SPE-M1.6-2-MC1(100) | M1.6 | 0.35 | 2 | 2.3 | 0.5 | SKCHB-M1.6 | 94 | 0.040 | 100 | 0.078 | 61.60 | CAD | Cart |

| SPE-M1.6-2.5-MC1(100) | M1.6 | 0.35 | 2.5 | 2.3 | 0.5 | SKCHB-M1.6 | 94 | 0.040 | 100 | 0.079 | 61.60 | CAD | Cart |

| SPE-M1.6-3-MC1(100) | M1.6 | 0.35 | 3 | 2.3 | 0.5 | SKCHB-M1.6 | 94 | 0.040 | 100 | 0.079 | 61.60 | CAD | Cart |

| SPE-M1.6-3.5-MC1(100) | M1.6 | 0.35 | 3.5 | 2.3 | 0.5 | SKCHB-M1.6 | 94 | 0.040 | 100 | 0.079 | 61.60 | CAD | Cart |

| SPE-M1.6-4-MC1(100) | M1.6 | 0.35 | 4 | 2.3 | 0.5 | SKCHB-M1.6 | 94 | 0.040 | 100 | 0.08 | 61.60 | CAD | Cart |

| SPE-M1.6-6-MC1(100) | M1.6 | 0.35 | 6 | 2.3 | 0.5 | SKCHB-M1.6 | 94 | 0.040 | 100 | 0.08 | 61.60 | CAD | Cart |

*1: Values in chart are for reference only. They are not guaranteed values. The recommended tightening torque is 50% of the torsional torque.

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form hereRelated Services

Material/Finish

| SPE-MC1 | |

|---|---|

| Main Body | PEEK (Polyether Ether Ketone) (Light Brown) |

| Heat Resistance Temperature*1 |

260℃ |

*1: This is the value for the resin material. The operating temperature of the product changes with performance conditions such as tightening torque.

Application

FPD production equipment / Semiconductor manufacturing equipment / Printed circuit board etching devices / Metallic surface treatment equipment and facilities / Chemical plants / Transformers / Electrical and electronic equipment / Hot water pumps / Chemical pumpsCharacteristics

- PEEK miniature screws for precision instruments (No. 0 Class 1).

- PEEK is a thermoplastic super engineering plastic superior in physical and chemical properties.

- Excellent chemical resistance. It remains almost unaffected by chemicals other than concentrated sulfuric acid, concentrated nitric acid, and concentrated hydrofluoric acid.

- With excellent heat resistance and water resistance, it retains strength at high temperatures.

- It features outstanding resistance to wear, shock, and fatigue.

- It also has high flame retardance which clears the UL 94 V-0 standard.

- For the properties and precautions for use of plastic screws, see “Properties of Plastic Screws.” ⇒Plastic Screws

- Mount and remove with SKCHB Dedicated Bits and SRD Dedicated Magnetic Screwdriver.