Specs/CAD

Unit : mm

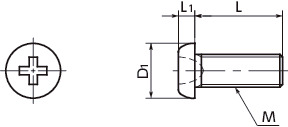

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | D1 | L1 | Cross-recessed Socket No. | Tensile Breaking Load (N)*1 |

Torsional Torque (N・m)*1 |

Qty per Pack | Mass (g) |

CAD Download |

RFQ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SPA-M1.2-1.5-MC | M1.2 | 0.25 | 1.5 | 1.8 | 0.5 | 0 | 98 | 0.029 | 10 | 0.014 | CAD | RFQ |

| SPA-M1.2-1.8-MC | M1.2 | 0.25 | 1.8 | 1.8 | 0.5 | 0 | 98 | 0.029 | 10 | 0.015 | CAD | RFQ |

| SPA-M1.2-2-MC | M1.2 | 0.25 | 2 | 1.8 | 0.5 | 0 | 98 | 0.029 | 10 | 0.015 | CAD | RFQ |

| SPA-M1.2-2.5-MC | M1.2 | 0.25 | 2.5 | 1.8 | 0.5 | 0 | 98 | 0.029 | 10 | 0.016 | CAD | RFQ |

| SPA-M1.2-3-MC | M1.2 | 0.25 | 3 | 1.8 | 0.5 | 0 | 98 | 0.029 | 10 | 0.017 | CAD | RFQ |

| SPA-M1.2-3.5-MC | M1.2 | 0.25 | 3.5 | 1.8 | 0.5 | 0 | 98 | 0.029 | 10 | 0.017 | CAD | RFQ |

| SPA-M1.2-4-MC | M1.2 | 0.25 | 4 | 1.8 | 0.5 | 0 | 98 | 0.029 | 10 | 0.018 | CAD | RFQ |

| SPA-M1.2-1.5-MC(100) | M1.2 | 0.25 | 1.5 | 1.8 | 0.5 | 0 | 98 | 0.029 | 100 | 0.014 | CAD | RFQ |

| SPA-M1.2-1.8-MC(100) | M1.2 | 0.25 | 1.8 | 1.8 | 0.5 | 0 | 98 | 0.029 | 100 | 0.015 | CAD | RFQ |

| SPA-M1.2-2-MC(100) | M1.2 | 0.25 | 2 | 1.8 | 0.5 | 0 | 98 | 0.029 | 100 | 0.015 | CAD | RFQ |

| SPA-M1.2-2.5-MC(100) | M1.2 | 0.25 | 2.5 | 1.8 | 0.5 | 0 | 98 | 0.029 | 100 | 0.016 | CAD | RFQ |

| SPA-M1.2-3-MC(100) | M1.2 | 0.25 | 3 | 1.8 | 0.5 | 0 | 98 | 0.029 | 100 | 0.017 | CAD | RFQ |

| SPA-M1.2-3.5-MC(100) | M1.2 | 0.25 | 3.5 | 1.8 | 0.5 | 0 | 98 | 0.029 | 100 | 0.017 | CAD | RFQ |

| SPA-M1.2-4-MC(100) | M1.2 | 0.25 | 4 | 1.8 | 0.5 | 0 | 98 | 0.029 | 100 | 0.018 | CAD | RFQ |

| SPA-M1.4-2-MC | M1.4 | 0.3 | 2 | 2 | 0.5 | 0 | 79 | 0.027 | 10 | 0.016 | CAD | RFQ |

| SPA-M1.4-2.5-MC | M1.4 | 0.3 | 2.5 | 2 | 0.5 | 0 | 79 | 0.027 | 10 | 0.017 | CAD | RFQ |

| SPA-M1.4-3-MC | M1.4 | 0.3 | 3 | 2 | 0.5 | 0 | 79 | 0.027 | 10 | 0.018 | CAD | RFQ |

| SPA-M1.4-3.5-MC | M1.4 | 0.3 | 3.5 | 2 | 0.5 | 0 | 79 | 0.027 | 10 | 0.018 | CAD | RFQ |

| SPA-M1.4-4-MC | M1.4 | 0.3 | 4 | 2 | 0.5 | 0 | 79 | 0.027 | 10 | 0.019 | CAD | RFQ |

| SPA-M1.4-6-MC | M1.4 | 0.3 | 6 | 2 | 0.5 | 0 | 79 | 0.027 | 10 | 0.022 | CAD | RFQ |

| SPA-M1.4-2-MC(100) | M1.4 | 0.3 | 2 | 2 | 0.5 | 0 | 79 | 0.027 | 100 | 0.016 | CAD | RFQ |

| SPA-M1.4-2.5-MC(100) | M1.4 | 0.3 | 2.5 | 2 | 0.5 | 0 | 79 | 0.027 | 100 | 0.017 | CAD | RFQ |

| SPA-M1.4-3-MC(100) | M1.4 | 0.3 | 3 | 2 | 0.5 | 0 | 79 | 0.027 | 100 | 0.018 | CAD | RFQ |

| SPA-M1.4-3.5-MC(100) | M1.4 | 0.3 | 3.5 | 2 | 0.5 | 0 | 79 | 0.027 | 100 | 0.018 | CAD | RFQ |

| SPA-M1.4-4-MC(100) | M1.4 | 0.3 | 4 | 2 | 0.5 | 0 | 79 | 0.027 | 100 | 0.019 | CAD | RFQ |

| SPA-M1.4-6-MC(100) | M1.4 | 0.3 | 6 | 2 | 0.5 | 0 | 79 | 0.027 | 100 | 0.022 | CAD | RFQ |

| SPA-M1.6-2.5-MC | M1.6 | 0.35 | 2.5 | 2.3 | 0.5 | 0 | 103 | 0.035 | 10 | 0.019 | CAD | RFQ |

| SPA-M1.6-3-MC | M1.6 | 0.35 | 3 | 2.3 | 0.5 | 0 | 103 | 0.035 | 10 | 0.02 | CAD | RFQ |

| SPA-M1.6-3.5-MC | M1.6 | 0.35 | 3.5 | 2.3 | 0.5 | 0 | 103 | 0.035 | 10 | 0.021 | CAD | RFQ |

| SPA-M1.6-4-MC | M1.6 | 0.35 | 4 | 2.3 | 0.5 | 0 | 103 | 0.035 | 10 | 0.022 | CAD | RFQ |

| SPA-M1.6-6-MC | M1.6 | 0.35 | 6 | 2.3 | 0.5 | 0 | 103 | 0.035 | 10 | 0.026 | CAD | RFQ |

| SPA-M1.6-2.5-MC(100) | M1.6 | 0.35 | 2.5 | 2.3 | 0.5 | 0 | 103 | 0.035 | 100 | 0.019 | CAD | RFQ |

| SPA-M1.6-3-MC(100) | M1.6 | 0.35 | 3 | 2.3 | 0.5 | 0 | 103 | 0.035 | 100 | 0.02 | CAD | RFQ |

| SPA-M1.6-3.5-MC(100) | M1.6 | 0.35 | 3.5 | 2.3 | 0.5 | 0 | 103 | 0.035 | 100 | 0.021 | CAD | RFQ |

| SPA-M1.6-4-MC(100) | M1.6 | 0.35 | 4 | 2.3 | 0.5 | 0 | 103 | 0.035 | 100 | 0.022 | CAD | RFQ |

| SPA-M1.6-6-MC(100) | M1.6 | 0.35 | 6 | 2.3 | 0.5 | 0 | 103 | 0.035 | 100 | 0.026 | CAD | RFQ |

*1: Values in chart are for reference only. They are not guaranteed values. The recommended tightening torque is 50% of the torsional torque.

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form here●When purchasing less volume than one full bag, a separate handling fee is charged. For details, see the Sold Separately Service.

Related Services

Material/Finish

| SPA-MC | |

|---|---|

| Main Body | RENYTM*1 (50% Glass Fiber Reinforced Polyamide MXD6) (Ivory) |

| Heat Resistance Temperature*2 |

105℃ |

*1: RENYTM is a trademark or registered trademark of Mitsubishi Gas Chemical Company, Inc.

*2: This is the value for the resin material. The operating temperature of the product changes with performance conditions such as tightening torque.

Application

Heat insulation and dew condensation prevention of refrigerating and freezing facilitiesElectrical and electronic equipment / Offshore instruments / Plating facilities

Characteristics

- RENYTM miniature screws for precision instruments.

- RENYTM is a thermoplastic engineering plastic with excellent tensile and bending strength.

- It is highly fatigue-resistant and has excellent creep and heat insulation properties.

- While it is nearly as strong as metal, its weight is approximately 1/5 of iron.

- For the properties and precautions for use of plastic screws, see “Properties of Plastic Screws.”⇒Plastic Screws